Separate collection and Recycling

Raccolta differenziata

Separate collection is one of the useful steps to ensure recycling and recovery of the materials present in waste. It consists in the manual separation of waste at the source, i.e. where it is generated (home, office, industrial plant, commercial premises, public spaces and so on). Once collected, the waste is sent for recycling

La raccolta differenziata in Italia (dati al 20191)

Italia: 61,35%

Nord: 69,60%

Centro: 58,13%

Sud: 50,63%

*ISPRA 2020

Types of separate collection

Mono-material

Citizens throw each type of waste (glass, paper, plastic, etc.) into separate containers.

Multi-material

Different waste types are collected in a single container, and then mechanically separated downstream of the collection.

Method of collection/conferment

Household (or “door-to-door”)

Waste collectors empty waste containers or collect bags directly from homes at fixed times.

Road/Curbside

Citizens take waste to skips/banks/bins located in the streets.

Recycling/disposal site

Some particular types of waste (cumbersome, green, WEEE and exhausted oils) are collected in specific areas before being sent to recovery plants.

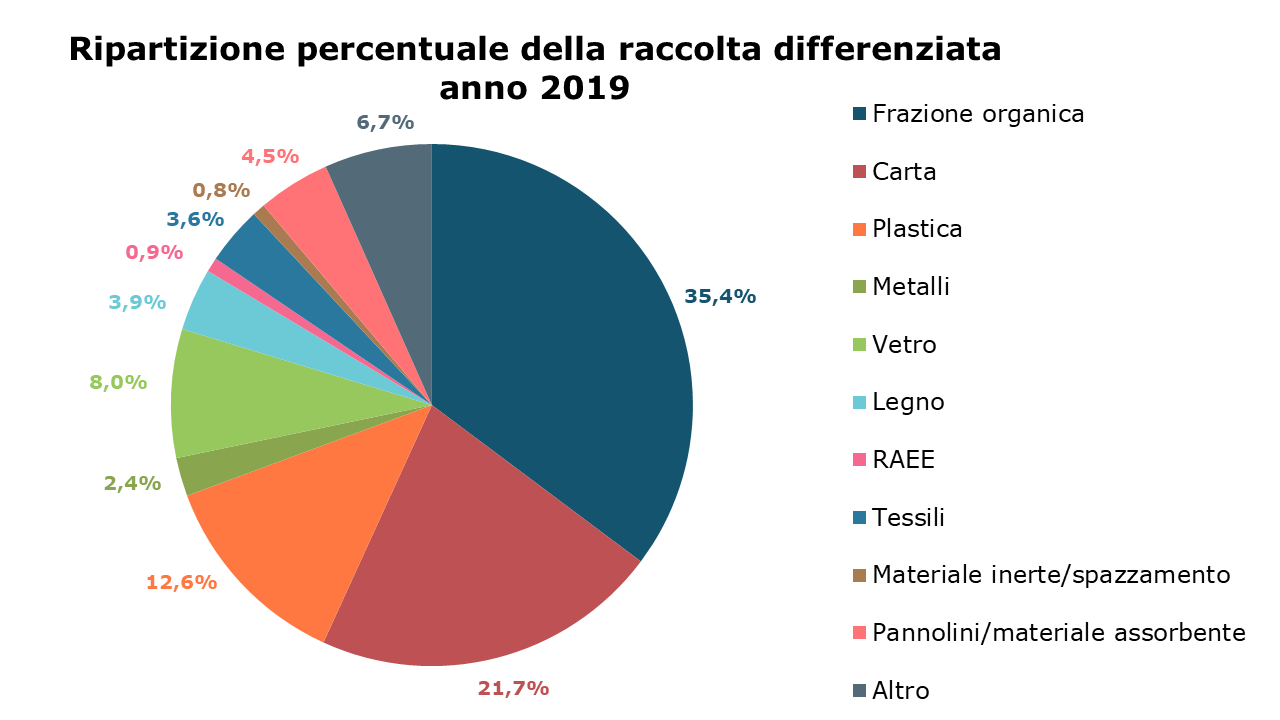

Riciclo dei rifiuti

Recyclingis the set of operations that results in recovery of products, materials or substances that can be reusable from waste: an initial selection phase, in which foreign materials are eliminated – residues of selection, then what remains is sent to the recycling plant.

Depending on what the waste is composed of, different treatment technologies are used: glass, paper, plastic, wood, alluminium, steel therefore follow very different recycling paths.

All waste generated must be recovered as much as possible, otherwise landfilling is necessary. Although the processes of materials recovery from waste are constantly evolving, recycling remains a complex operation which in turn generates additional residues.

The materials deriving from the recycling process are defined as i Secondary Raw Materials (MPS) and may be used as substitutes, totally or in part, for corresponding virgin raw materials.

Goals for 2035

Recycling and preparation for reuse of 65% by weight of at least paper, metals, plastic, glass, and textiles, from 1 January 2025.

Advantages of recycling

Saves raw materials

Reduces use of landfill

National data at 2018

55 % of municipal waste is prepared for reuse and recycling

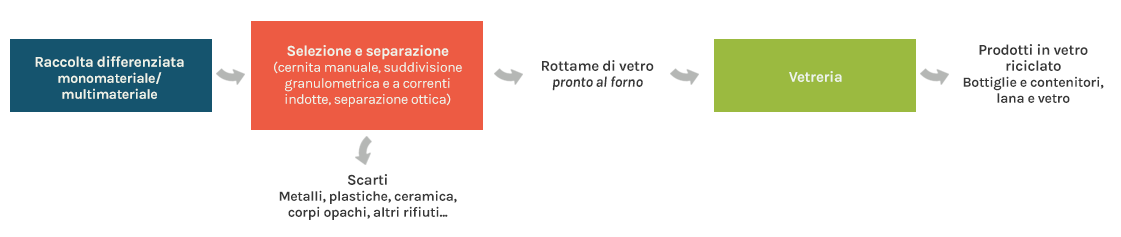

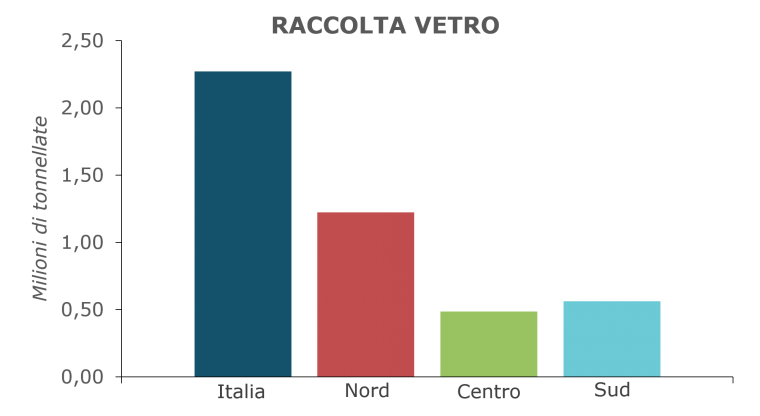

Glass recycling

Glass waste is mainly made up of green, brown or transparent bottles and containers, and to a lesser extent glasses and plates.

Collection in roadside bins only for glass has over the years ensured best results in terms of “purity” of the collected material, as it minimizes contamination from other waste materials. Residual impurities are removed in glass recycling plants equipped with advanced technology for the selection and separation of glass from foreign matter.

At this point it is considered “ready for the oven” and is sent to glass factories to be recast together with raw materials, to obtain new products.

Almost all recycled glass is used to make new bottles and containers (on average each new glass item contains 30% of recycled material), while a small amount is used to produce fiberglass .

BENEFITS OF RECYCLING GLASS

Energy savings due to lower temperature required for melting, compared to raw materials: 0.15 toe saved for every tonne of glass recycled.

Reduction of atmospheric emissions related to production: 0.7 t of CO2eq avoided for every tonne of glass recycled.

toe: tonnes of oil equivalent

CO2eq: CO2 equivalent

1 ISPRA 2020 2 CoReVe

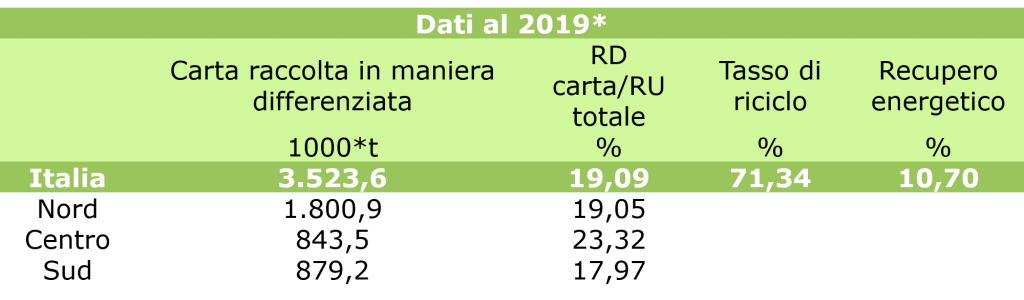

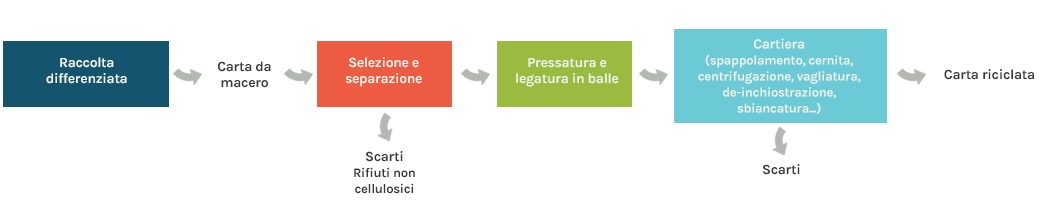

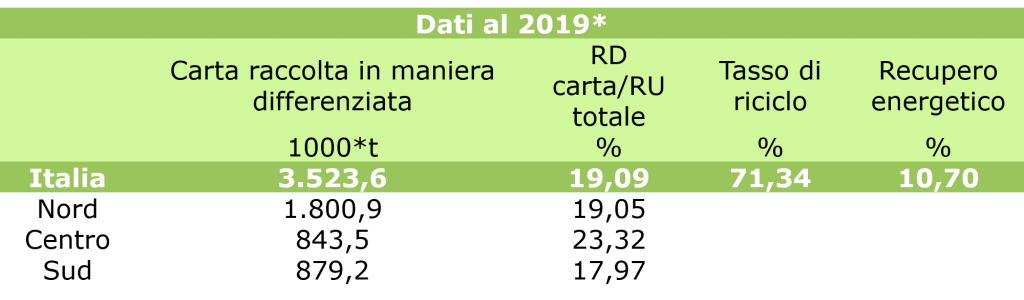

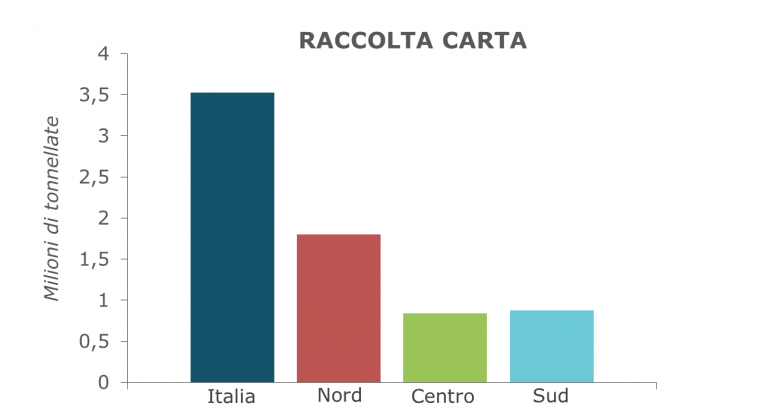

Paper recycling

Paper and cardboard waste mainly comes from separate collection of municipal solid waste. The first step in recycling separately-collected material consists in separating paper from cardboard by weight and consistency.

According to the norm (norma UNI EN 643:2002) the cellulosic materials selected take the name of pulper and are categorized in 5 groups, from that of “ordinary quality” to that of “special quality” according to the physical-chemical properties.

After being pressed and packaged in bales, pulper is sent to paper mills, where it is reduced to a paste before being mixed with virgin cellulose pulp, to produce new items in recycled paper.

Paper cannot be recycled indefinitely, as the treatments reduce its quality due to the degradation of cellulose fibers: on average, it tends not to be recycled more than 5 times.

BENEFITS OF RECYCLING PAPER

Energy savings: 0.19 toe saved for every tonne of paper recycled.

Reduction of atmospheric emissions related to production: 1.1 t of CO2eq avoided for every tonne of recycled paper.

toe: tonnes of oil equivalent

CO2eq: CO2 equivalent

1ISPRA 2020

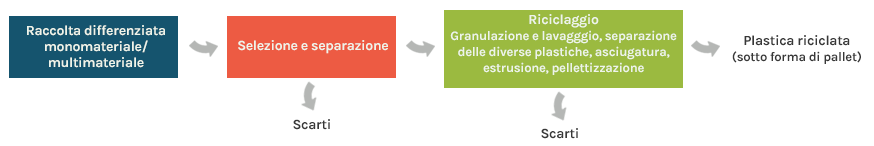

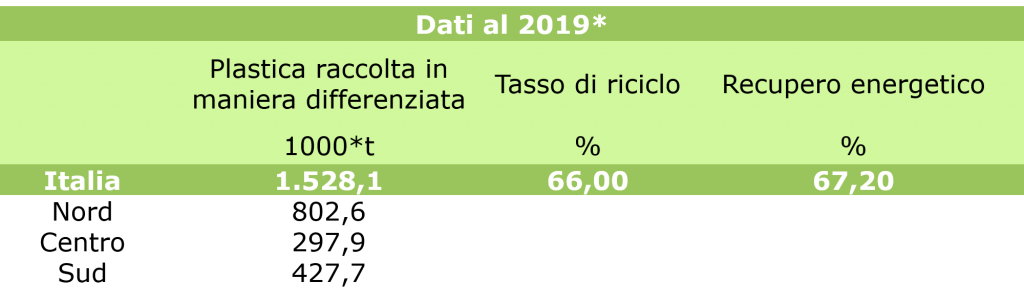

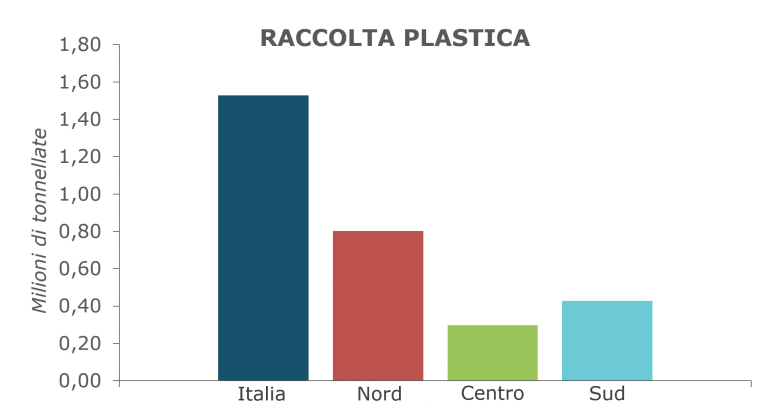

Plastic recycle

The recovery of plastic waste is particularly difficult, when compared to that of other materials. This is due to the heterogeneity of the polimers that make up packaging. What is normally considered as “plastic” is in fact a very large and heterogeneous set of different chemical compounds.

The mechanical recycling process involves shredding, washing, drying, extrusion and granulation, leading to the production of recycled plastic in the form of flakes or granules. In practice, the uses for the polymers obtained from recycling are limited by costs and the qualitative characteristics of recycled plastic: part of the recovered material is not suitable for use in the production of original packaging, but is used for less valuable items (e.g. urban furnishing objects).

In addition to mechanical recycling, there are several recovery technologies for plastic packaging: Chemical recycling, still not widespread, and energy recovery.

Chemical recyclingo involves the decomposition of polimers to rerturn to the original monomers which can be re-injected into the production cycle of plastics or petrochemical products. There are several processes through which chemical recycling is carried out: hydrogenation (degradation by oxygen and heat), pyrolysis and gasification.

Waste from the plastic recycling process generally goes to a energy recovery, but can also be used in steelworks as an SRA (Secondary Reducing Agent) i.e. as a reducing agent during furnace oxidation reactions, replacing up to 20 % of the coke normally used for this purpose.

BENEFITS OF RECYCLING PLASTIC

Energy saving: 0.4 ÷ 0.9 toe saved for every tonne of plastic recycled.

Reduction of emissions into the atmosphere related to production: 0.4 ÷ 1 t of CO2eq avoided for every tonne of plastic recycled.

toe: tonnes of oil equivalent;

CO2eq: CO2 equivalent

1ISPRA 2020

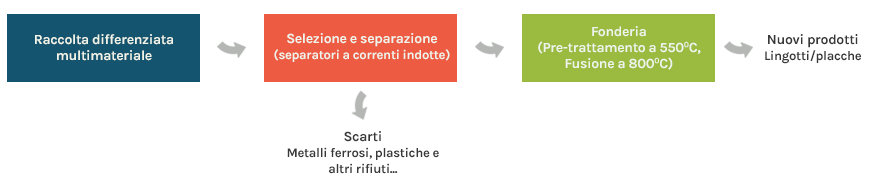

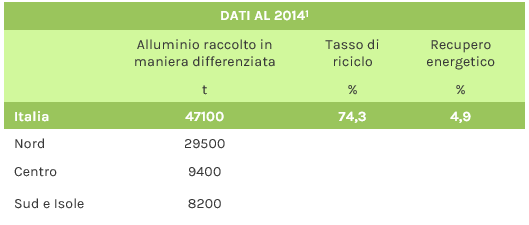

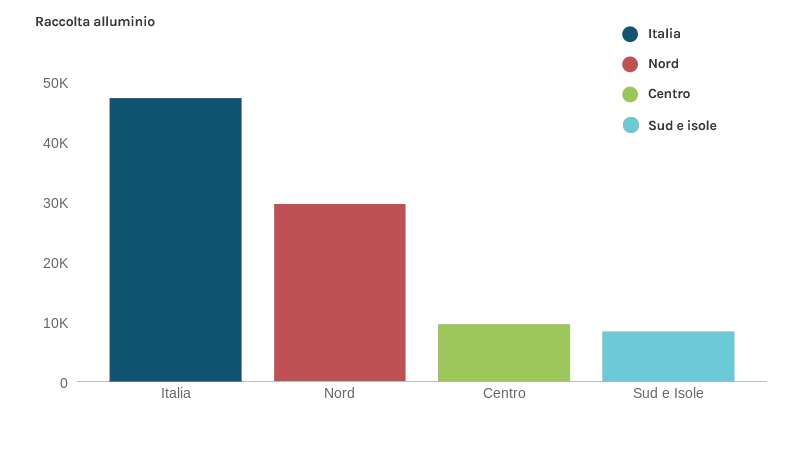

Aluminum recycling

Aluminum is very suitable for recycling because it can be subjected to an infinite number of cycles without suffering significant loss of quality: secondary aluminum is therefore equivalent to primary metal.

There are also numerous environmental benefits from recycling aluminum: the production of 1 kg of secondary aluminum requires 5 % of the energy consumption necessary for the production of metal from the mineral (bauxite). For the same reason, aluminum recycling is cost-effective.

The recycling process involves an initial phase of selection and separation from foreign materials and then sending the aluminum to a foundry to be subjected to fusion and formed into ingots.

BENEFITS OF RECYCLING ALUMINIUM

Energy saving: 3 toe per tonne of aluminum recycled.

Reduction of emissions into the atmosphere related to production: 6.3 t CO2eq avoided for every tonne of aluminum recycled.

toe: Tonnes of oil equivalent

CO2eq: CO2 equivalent

1CiAL – Gestione e Bilancio 2014

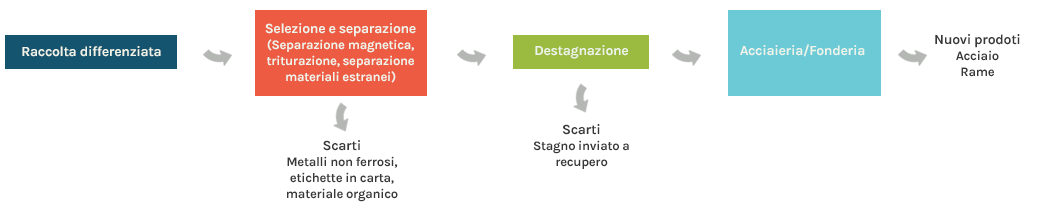

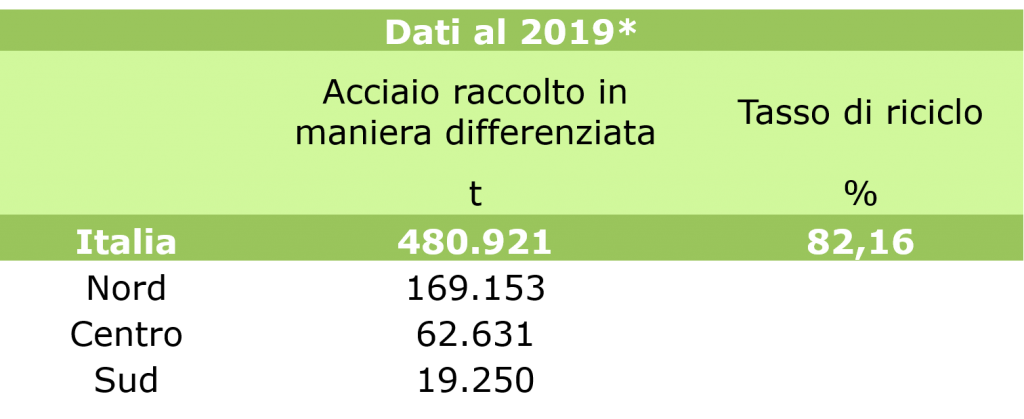

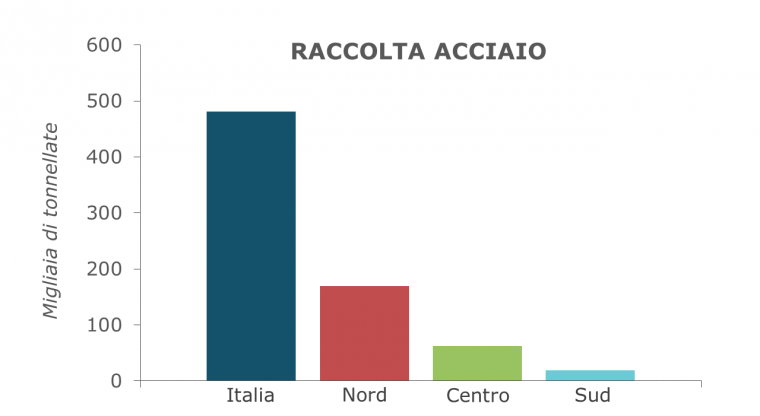

Steel recycling

Steel in urban solid waste is normally present in the form of cans and containers, and its use has been decreasing as a result of the increase in aluminum cans and plastic containers.

The initial step of the recovery process involves magnetic separation of ferrous materials, which are subsequently shredded in order to facilitate separation from foreign materials.

For steel packaging it is necessary to remove tinplate. In this way the materials obtained can be recycled in steel mills/foundries in the production of new steel.

BENEFITS OF RECYCLING STEEL

Energy saving: 0.3 toe saved for every tonne of steel recycled.

Reduction of atmospheric emissions related to production: 1.1 t of CO2eq avoided for every tonne of steel recycled.

toe: tonnes of oil equivalent

CO2eq: CO2 equivalent

1RGPS Ricrea, 2019

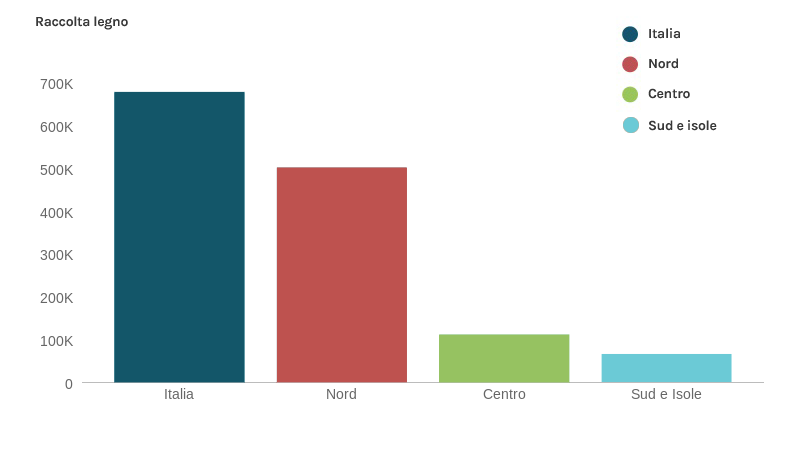

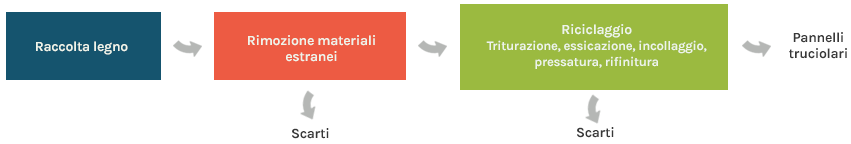

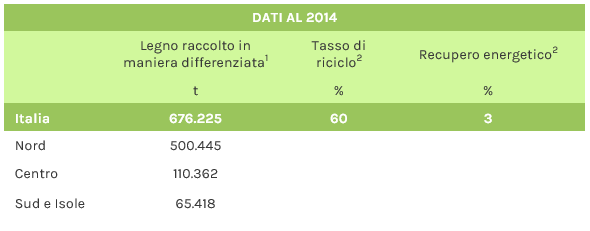

Wood recycling

Almost all recycled wood is used for the production of chipboard panels for the furniture industry.

It can also be used to produce cellulose pulp for paper mills.

After the removal of foreign materials, the wood is shredded, dried, glued, pressed and finished.

Wood residues can be sent to waste-to-energy plants to produce electrical and thermal energy.

BENEFICI DERIVANTI DAL RICICLO DEL LEGNO

Riduzione delle emissioni in atmosfera connesse all’attività produttiva: 1,17 t di CO2eq evitate per ogni tonnellata di legno riciclato.

CO2eq: CO2 equivalente

1Rapporto ISPRA, 2015

2L’Italia del riciclo, 2015