TMB

Il Trattamento Meccanico Biologico (TMB)

Mechanical Biological Treatment is a system for the treatment of Residual Urban Waste (RUW) which normally involves biological stabilization of the organic component and mechanical refining.

TMB is an intermediate type of treatment: all the outgoing products either require further treatment in other plants or are taken for disposal in landfills.

Objectives may differ:

simple pre-treatment of waste before sending it to landfill;

production of Refuse Derived Fuel (RDF), intended for energy recovery (waste-to-energy, cement factories);

recovery of materials to be sent for recycling.

The configuration of the plant varies according to the fractions to be recovered and the type of incoming waste. Three main plant designs can be identified:

Single flow MTB:

Waste is fully subjected to biological stabilization, in order to reduce humidity and the presence of organic matter (bio-drying process)(si parla di processo di bio-drying). Downstream of this first phase, the different fractions destined for material or energy recovery are separated mechanically.

Separate flow MTB:

Organic matter is first separated and stabilized (through an aerobic or anaerobic process) and then sent to landfill. The remaining portion of waste is subjected to a series of mechanical processes to recover the materials present for recycling or energy recovery (RDF).

Mechanical treatment:

This configuration does not involve the biological stabilization phase, but only the mechanical processes.

It is typically used for Urban Residue Waste (RUW), where upstream quality separate collection of organic matter is carried out, leading to resulting residual organic content of less than 10%.

If the aim is to recover materials and then recycle them, such plants are also referred to as Material Recovery Facility (MRFs).

The main mechanical treatments in this type of system are:

- Screening;

- Shredding;

- Magnetic separators for ferrous metals;

- Induced current separators for non-ferrous metals;

- Ballistic separators;

- Optical separators for plastics.

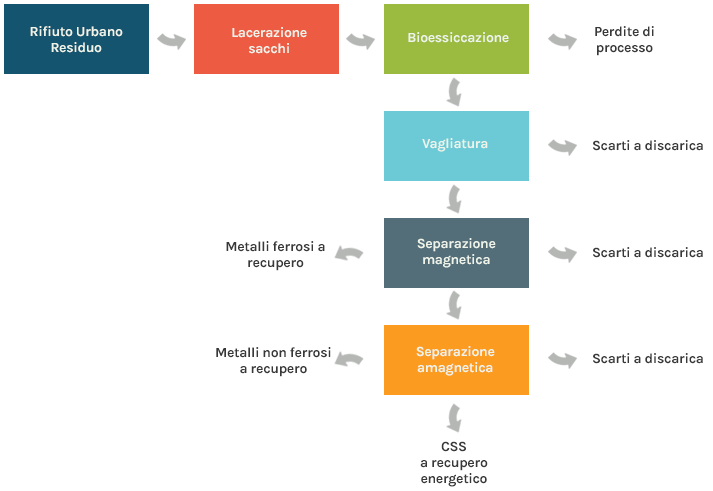

Il TMB a flusso unico

Examples of configuration: Single-flow MBT

All incoming waste undergoes the bio-drying phase.bio-drying.

The plant layout aims to improve the energy quality of the RDF produced, not to maximize recyclable materials (ferrous and non-ferrous metals). RDF

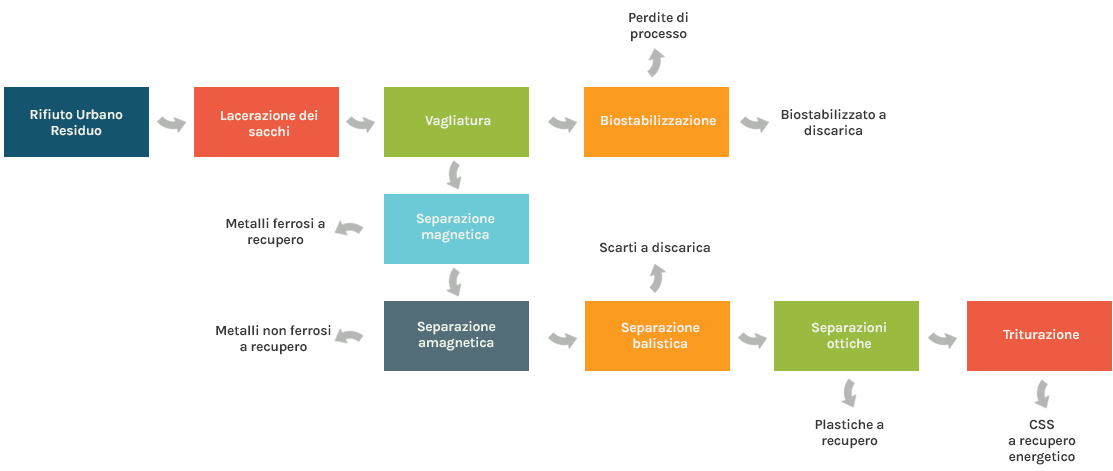

Il TMB a flusso separato

Examples of configuration: Separate flow MBT

Only the organic part of the waste undergoes the bio-stabilization phase, with the production of bio-stabilized material for landfill.

The layout of the plant permits the separation of metals and plastics, and possibly even paper, of a quality not compromised by biological treatment.

Ballistic separators divide plastics in film form from bottles and containers, while optical separators enable separation of the different polymers.